Summary

Company Logo

Key market opportunities in the sustainable steel sector include: investing in green technologies and renewable energy, adopting electric arc furnace and molten oxide electrolysis, advancing material sciences for high-strength steel, enhancing supply chain transparency, and leveraging …

Source: Yahoo Finance

AI News Q&A (Free Content)

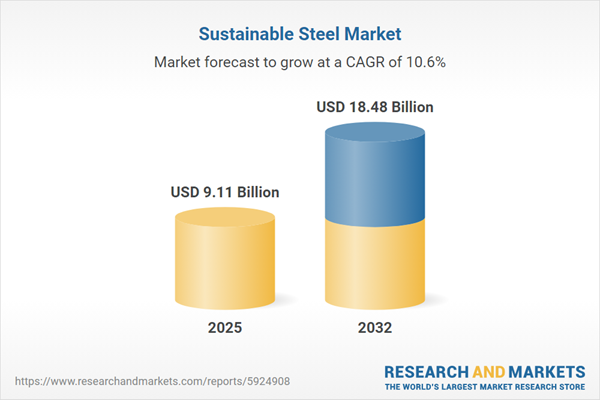

Q1: What are the projected growth rates and factors driving the sustainable steel market between 2025 and 2032?

A1: The sustainable steel market is expected to grow from USD 9.11 billion in 2025 to USD 18.48 billion by 2032, with a compound annual growth rate (CAGR) of 10.57%. This growth is driven by the adoption of low-carbon production models, increased investment in green steel processes, and global shifts towards sustainability. The market is also bolstered by regulatory pressures and innovations in production technologies.

Q2: How does the circular economy model contribute to the sustainability of the steel industry?

A2: The circular economy model emphasizes sharing, leasing, reusing, repairing, refurbishing, and recycling materials to extend their lifecycle, thereby reducing waste and carbon emissions. In the steel industry, adopting circular economy principles can significantly decrease resource consumption and emissions, creating new market opportunities and enhancing sustainability.

Q3: What challenges do high silicon steel production face, and what innovations have been made to address them?

A3: High silicon steel offers excellent magnetic properties but is difficult to produce due to its high brittleness. Innovations like the Double Glow Plasma Surface Metallurgy Technology have simplified production without pollution, potentially enabling large-scale production. This could significantly impact the energy and aerospace industries by saving energy and reducing costs.

Q4: What role does iron play as a sustainable chemical carrier in renewable energy production, and how does it relate to steel production?

A4: Iron can serve as a sustainable chemical carrier by being used in retrofitting coal-fired plants for iron combustion, producing CO2-free electricity. The process involves recycling iron oxides back to metallic iron using hydrogen, creating a circular energy economy. This aligns with steel industry decarbonization efforts and could support sustainable electricity and hydrogen production.

Q5: How is the hydrogen plasma reduction of iron ore contributing to sustainable steel production?

A5: Hydrogen plasma reduction offers a sustainable method for reducing iron ore, resulting in lower carbon emissions compared to traditional methods. This process is being explored to produce green steel, contributing to the steel industry's efforts to reduce its carbon footprint and meet environmental regulations.

Q6: What are the key trends and technologies driving the transition to green steel?

A6: Key trends include the adoption of electric arc furnaces (EAFs) and hydrogen-based steelmaking to reduce CO2 emissions. The transition is driven by environmental regulations, investor pressure, and technological advancements in green steel production, such as using renewable energy sources and innovative recycling methods.

Q7: How does the global shift towards green steel impact the steel market's economic and environmental landscape?

A7: The shift towards green steel is expected to transform the steel market significantly, with projections indicating a rise in market value from USD 12.3 billion in 2025 to USD 129.1 billion by 2032. This transition is driven by climate change concerns, high capital investments, and the adoption of circular economy initiatives, which aim to reduce environmental impact while meeting growing demand.