Summary

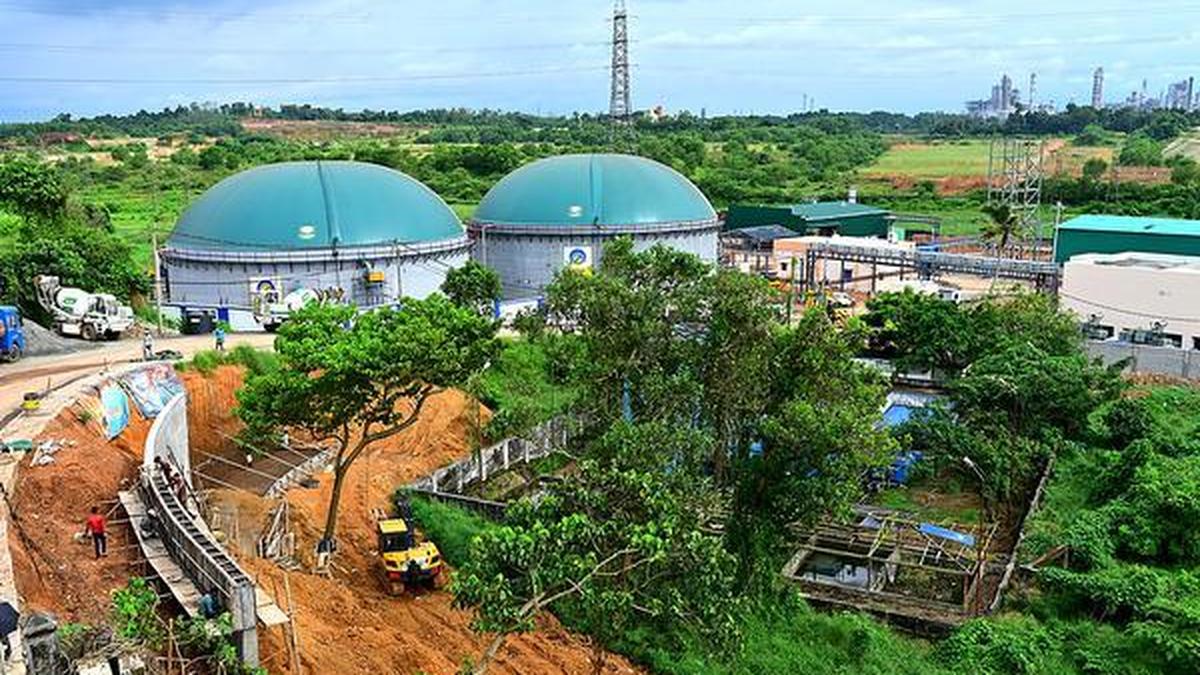

The Brahmapuram biogas plant in Kochi, inaugurated by CM Vijayan, will produce 6 tonnes of CBG and 128 tonnes of manure.

Source: thehindu.com

AI News Q&A (Free Content)

Q1: What are the expected environmental benefits of the Brahmapuram biogas plant in Kochi?

A1: The Brahmapuram biogas plant is anticipated to provide significant environmental benefits by converting organic waste into biogas and organic manure. This process reduces landfill waste, decreases greenhouse gas emissions by capturing methane, and produces renewable energy in the form of Compressed Biogas (CBG). The plant is estimated to generate 6 metric tonnes of CBG and 128 tonnes of organic manure, contributing to a circular economy and reducing reliance on fossil fuels.

Q2: How does the anaerobic co-digestion process enhance biogas production?

A2: Anaerobic co-digestion involves the simultaneous degradation of multiple waste types, such as slaughterhouse wastewater and food waste, enhancing biogas production. A study highlighted the use of ferric oxide as a conductive material in this process, which significantly improved methane yield and system performance. The optimal use of ferric oxide increased biogas production by 81% due to enhanced microbial activity and reduced inhibitory compounds.

Q3: What challenges are associated with biogas plants, like the one in Kochi?

A3: Biogas plants face several challenges, including the need for consistent feedstock supply, managing the variability of organic waste, and ensuring efficient process control. Additionally, there are environmental concerns related to the handling of digestate, potential odors, and the need for advanced technology to optimize biogas yield and quality.

Q4: What are the economic implications of the Brahmapuram biogas plant?

A4: The Brahmapuram biogas plant is likely to have positive economic implications by reducing waste management costs and generating renewable energy. It provides a sustainable waste treatment solution while creating job opportunities in plant operations and maintenance. The production of organic manure also supports agricultural activities, potentially reducing the cost of chemical fertilizers.

Q5: How does the use of biogas as a renewable energy source impact carbon emissions?

A5: Biogas as a renewable energy source significantly reduces carbon emissions by capturing methane, a potent greenhouse gas, and converting it into energy. This process mitigates the environmental impact of organic waste decomposition in landfills. Furthermore, using biogas reduces dependency on fossil fuels, contributing to a lower carbon footprint and supporting climate change mitigation efforts.

Q6: What advancements in biogas technology are highlighted in recent research?

A6: Recent advancements in biogas technology include the use of conductive materials like ferric oxide to enhance biogas yield through improved microbial activity and digestion efficiency. Other innovations involve optimizing feedstock combinations and employing kinetic modeling to predict and enhance methane production. These advancements pave the way for more efficient and scalable biogas production systems.

Q7: What role do biogas plants play in sustainable waste management?

A7: Biogas plants play a critical role in sustainable waste management by converting organic waste into valuable resources like biogas and organic fertilizers. This reduces landfill use, minimizes waste-related emissions, and supports renewable energy generation. Biogas plants contribute to creating a circular economy by transforming waste into energy and nutrient-rich products, promoting environmental sustainability.

References:

- Enhanced Biogas Production via Anaerobic Co-Digestion of Slaughterhouse and Food Waste Using Ferric Oxide as a Sustainable Conductive Material

- Improving lipid and metabolite production in Haematococcus pluvialis using carbon-based quantum dots: a sustainable approach for biofuel and bioproduct development